Our cleanroom wall panels are engineered for effortless installation, practical functionality, and maximum flexibility, allowing spaces to be easily adapted or reconfigured. Whether you’re expanding, modifying, or building a new facility, our diverse range of materials and designs ensures the perfect solution for your unique application.

Each modular cleanroom wall panel features a fully sealed, robust construction with extruded aluminum profiles for a secure perimeter and high-density insulation at the core, delivering exceptional strength, stability, and long-term performance.

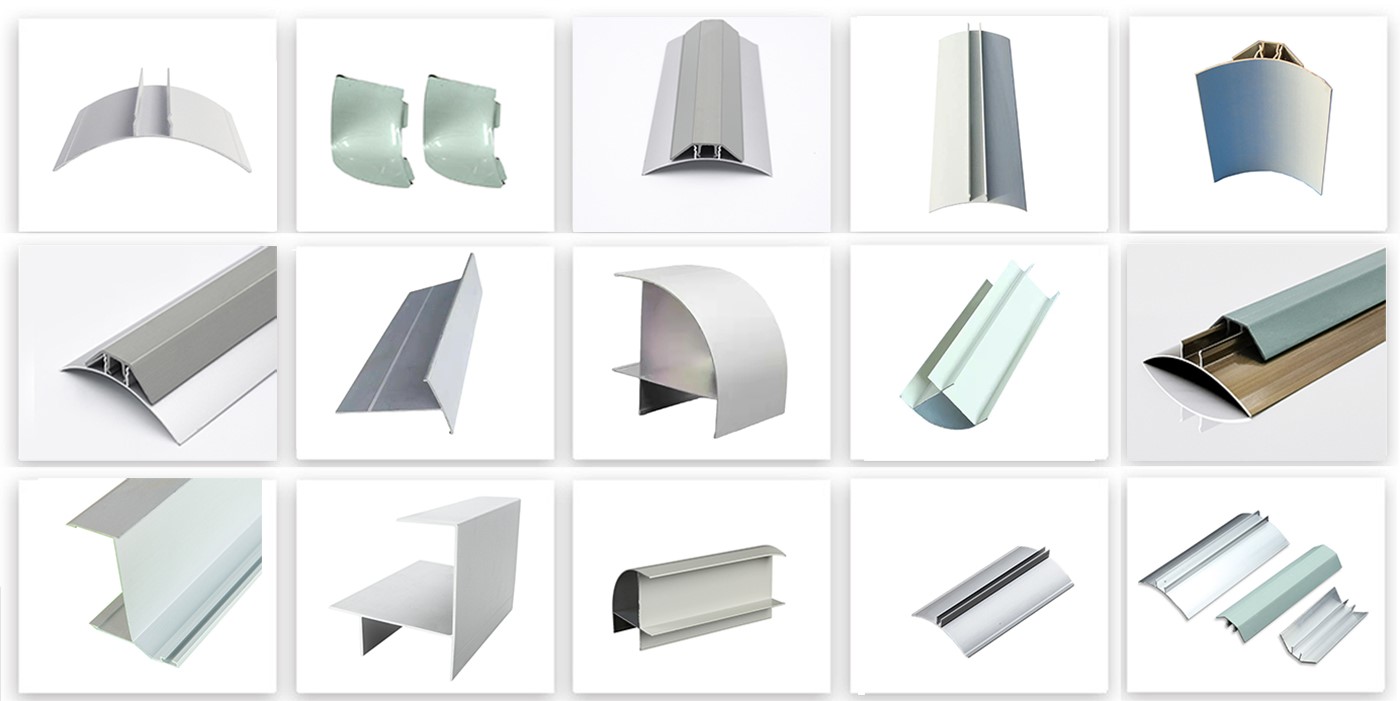

Our Portfolio of prefabricated wall panel materials and designs

Pre-Coated or Powder Coated

Stainless Steel

High-Pressure Laminate (HPL)

Panel Insulation for Modular Walls

Insulation is a technique used in modular cleanroom walls to prevent the transfer of various forms of energy, such as electricity, moisture, heat, or sound, from one medium to another.

Rockwool Infill

Poly Urethane Foam (PUF) Infill

Polyisocyanurate -(PIR) Infill

Clean room Wall Panels with Integrated Utilities

Our modular wall panels are designed not just for structural performance, but also to house and route essential electrical and mechanical utilities, ensuring a controlled, efficient, and clutter-free environment.

Electrical Integration

Our Modular Wall Panels are engineered to simplify electrical infrastructure, ensuring safety, reliability, and efficiency in controlled environments.

Power Distribution

Panels can embed conduits, raceways, and junction boxes, ensuring clean power routing to equipment and lighting without external clutter.

Control Systems

Panels support wiring for PLCs, sensors, and automation, enabling seamless process control and facility management.

Data/Telecom

Network cabling, fiber optics and communication lines can be housed within panels, protecting connections and ensuring fast, reliable data transfer.

Emergency Systems

Panels can house wiring for fire alarms, emergency lighting, and safety systems, ensuring compliance and occupant protection.

Mechanical Integration

HVAC Systems

Panels can house supply and return ducts, ensuring balanced airflow and compliance while reducing obstructions.

Piping Systems

Plumbing, compressed air, and gas lines can be cleanly integrated within panels for a sterile environment.

Vacuum Systems

Panels can route vacuum piping for material handling, sampling, and testing without affecting cleanroom integrity.

Process Utilities

Steam, chilled water, and other utility lines can be incorporated for flexible industry use.

Built in Air Returns

Space Efficiency

Integrating low air returns within the wall panel cavity minimizes the need for bulky, floor-mounted return grilles, saving valuable floor space within the cleanroom.

Maximized Footprint

By reducing the space occupied by the air return system, the overall building footprint can be smaller, potentially leading to cost savings in construction and reduced.

Wall Panels Benefits